What is a Cryogenic Air Separation Unit?

A cryogenic air separation unit is a device that compresses and cools air to a liquid state, then separates it into oxygen, nitrogen, and argon through distillation.

In 1935, Taiyo Nippon Sanso succeeded in domestically producing Japan's first air separation unit.

Leveraging our extensive experience and advanced technological capabilities, we have numerous installations both domestically and internationally, ranging from the largest-class air separation units to small-scale units for the semiconductor industry, earning high trust from our customers.

.png?701)

Basic Principle

<Air Separation Unit> Compressed air is cooled inside a cold box (insulated outer tank),

separated into oxygen (-183°C), nitrogen (-196°C), and argon (-186°C) through distillation utilizing the difference in boiling points.

Product Lineup (Standard Lineup)

- Our representative products in cryogenic air separation units include nitrogen generation units and air separation units.

- For customers who only require nitrogen production, please refer to the standard lineup of nitrogen generation units below.

- For nitrogen units outside of our lineup and air separation units intended for oxygen extraction or liquefaction purposes, please contact us individually for inquiries.

.png?1126)

Product Introduction

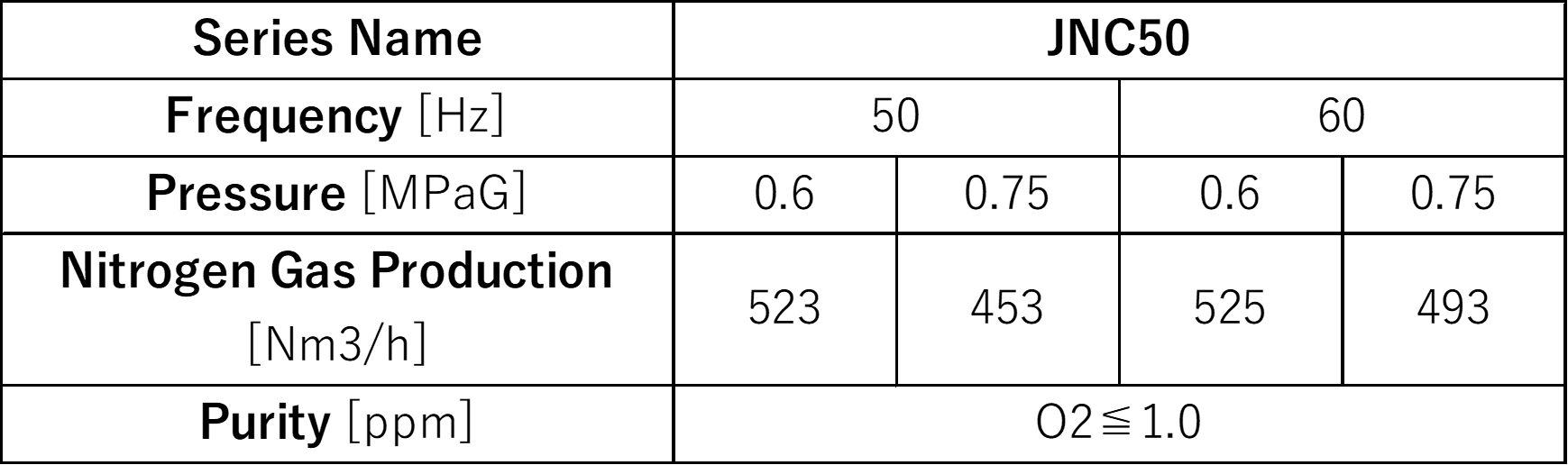

Nitrogen Generation Unit (JNC Type Nitrogen Generation Unit)

Features

-

Adoption of air-cooled process

No need for cooling water, cooling tower, or water quality management

-

Space-saving unit structure

-

Turbine-less process

Cold supply through liquefied nitrogen

-

Environmental measures

Adoption of ambient temperature MS adsorption technology

(no need for freon refrigerator)

-

Oil-free

Use of oil-free air compressor and prevention of oil contamination in product nitrogen

Nitrogen Generation Unit (JNF Type Nitrogen Generation Unit)

特徴

- Maintenance-free

Adoption of in-house manufactured (domestic) gas bearing expansion turbine for cold supply

⇒Reduction of constant LN2 injection for cold supply (continuous operation possible with only electricity and water even during disasters)

- Introduction of high-performance

oil-free water-cooled screw compressor with inverter (INV)

⇒Optimal operation according to usage (power reduction during reduced output)

Adoption of ambient temperature catalyst (impurity removal) *Option

- Space-saving layout

Free layout possible as each unit is independent

⇒Free layout possible as each unit is independent

Effective use of space

⇒Installation possible for each unit

Adoption of in-house manufactured packed distillation column

Adoption of in-house manufactured packed distillation column

⇒Realization of space and cost reduction through slimming of cold box due to reduced pressure loss

Nitrogen Generation Unit (JNR Type Nitrogen Generation Unit)

Features

- High-performance high-purity compatibility

⇒Each impurity below 0.1ppm

Adoption of in-house developed expansion turbine

⇒Adoption of expansion turbine-driven low-temperature compressor

-

Adoption of oil-free water-cooled screw compressor

Compact design, high efficiency (electricity cost reduction through flexible operation), prevention of oil contamination in product nitrogen

- Waste gas circulation and partial vaporization process using low-temperature compressor (in-house developed)

Low power consumption and high-efficiency process

- LN2 injection method

Efficient cold supply

- Space-saving

Soundproof panel integrated unit structure

⇒Low unit consumption and high yield process

Nitrogen Generation Unit (GNS Type Nitrogen Generation Unit)

Features

- Short delivery time

- Realization of short delivery time and cost minimization

Achieved through standard design and reduced on-site construction

- Realization of minimized on-site construction period through modular design Accommodates wide operating range

Free selection of product volume and pressure to suit customer needs

- Adoption of in-house manufactured gas bearing turbine

Oil-free type, reducing maintenance effort

- Oil-free

Adoption of oil-free air compressor

.png?692)

On-site & Plant Unit

Plant Sales Division

Plant Sales Department

6-2 Kojima-cho, Kawasaki-ku, Kawasaki-shi, Kanagawa 210-0861 Japan